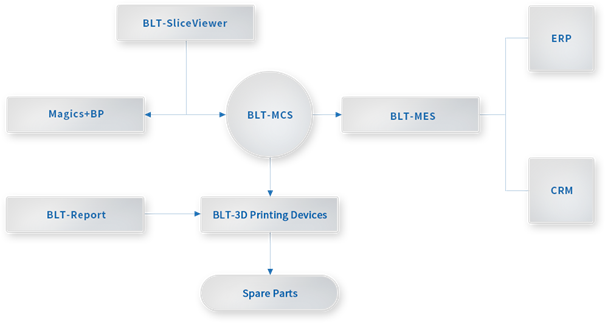

BLT additive manufacturing firm independently developed 3D metal printer software. BLT-MCS for real-time inspection of 3D metal printer devices; data segmentation and measurement software BLT-Slice Viewer; BLT-Report and BLT-MES smart product management software are used for report statistics.

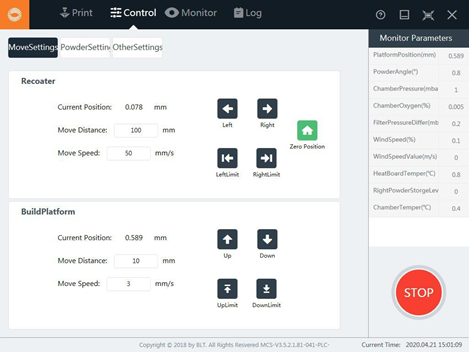

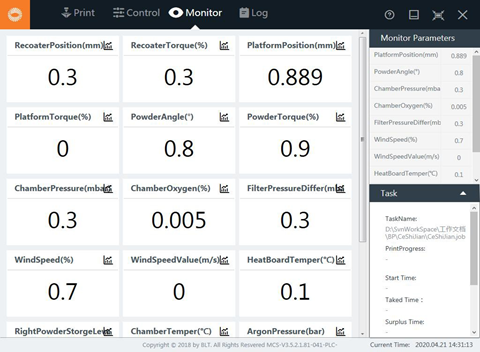

BLT-MCS, 3D Metal printer devices real-time software

1. Manual Control; BLT-MCS software can be used to manually control equipment such as scraper, work platform, spindle and solenoid valve.

2. Automatic Printing; BLT-MCS can perform automatic printing depending on the operator's settings. The operator can choose the starting print layers, the finished print layers, the print method and the powder spreading method. During the automatic printing process, the operator can also set device parameters such as powder delivery amount and powder spreading rate.

3. Process Monitoring; BLT-MCS has real-time monitoring functions such as dust spreading quality, scanning quality detection and stress area detection.

4. Traceable Quality Process; The BLT-MCS can create a log of equipment operations and can be displayed as log, time or log levels. Also, the log is saved in the database, which cannot be deleted. Problems can be analyzed with the data report during the printing procedure.

5. Auto Binding; using multiple galvanometers, BLT-MCS can implement the automatic split joint function, which improves the printing efficiency of devices while allowing for more internal quality.

6. Automatic (Grafting) Correction; With the help of BLT-MCS, high precision industrial cameraa combined with software algorithm, we can achieve cost savings effectively and ensure the accuracy and efficiency of the Grafting process.

BLT-SliceViewer

Data Segmentation and Measurement Software

1. Route Prediction; With BLT-Slice Viewer, you can check the working route of the galvanometer.

2. Craft Information Check; With BLT-Slice Viewer, it can control the scanning speed and power.

3. CAD Measurement; BLT-Slice Viewer can perform distance and angle measurements of vectors in print format.

4. Error Diagnosis in Business Documents; BLT-Slice Viewer can detect the error of attributed business documents and report the failure back to the operators via CPM.

5. Machine Hour Calculation; BLT-Slice Viewer calculates offline machine hours for items to be printed.

6. Counting Functions; BLT- Slice Viewer counts area by type of vectors as well as length of scan route and jump route.

BLT-Report

Report statistics software

1. Equipment Operation Reports; It can export all reports of MCS operation records.

2. Equipment Operation Report; It can export the statistical report of equipment working status, such as equipment lighting rate and equipment failure rate, within a certain period of time.

3. Logic Report Printing can realize the report export function of background action in the process of automatic printing.

4. Printing Parameter Report; can export reports on the oxygen content of the forming chamber and the height of the processing platform.

BLT-MES

Intelligent product line management software

1. Energy Monitoring; Energy monitoring system is energy monitor of water, electricity and gas in 3D printing workshop.

2. Equipment Monitoring: The equipment monitoring system realizes the online monitor of the working status of the 3D metal printer devices installed in the system.

3. Parts Circulation; The parts circulation system performs the online flow of the lifecycle of the 3D printing product line, from order entry to product storage.

4. Smart Order; The smart ordering system performs the function of automatically sorting 3D printing tasks according to conditions such as customers' level, task priorities and equipment conditions.

5. Equipment Management; The equipment management system handles the export of monthly, seasonal and annual quality reports as well as quality monitoring, faulty product handling throughout the entire 3D printing product line and part circulation process.

6. Warehouse Management; The warehouse management system can realize the intelligent management of the raw material warehouse, the finished product warehouse and the waste warehouse of the 3D printing product line.

7. Statistics Report; Statistical report system can perform business data analysis of 3D printing product line and reports on output quality and production operation

|

Print Strategy Machine Parameter Settings Slice Setting |

Contour Selection Chessboard style Montage Band-style Fitting Unordered Assembly Unidirectional Scan Reciprocating Scan Shortest Path Optimization Strip Width Lane Turn Boost Starting Point Distribution Air Flow Angle Prohibit Range of Airflow Angle Scaling Slice Thickness Gap-filling Triangles Optimization Contour Filtration Scan Order Radius Compensation Contour Offset Contour Data Contour Cutting Blocking the Path Scan Speed Practice Dimensions Wind Scanning Short Vector Combination Deselect Energy Uniformity Limit Corner Angle Remelting Times top surface lower surface Thickness of Sub-Surface |